The possibilities created by automation are a prerequisite for efficient industry. The number of products and product variations increases and it causes pressure for production automation. Production flexibility must increase as lead times become shorter and batches become smaller. At the same time work must flow smoothly, so that the right things are done at the right time using the right materials.

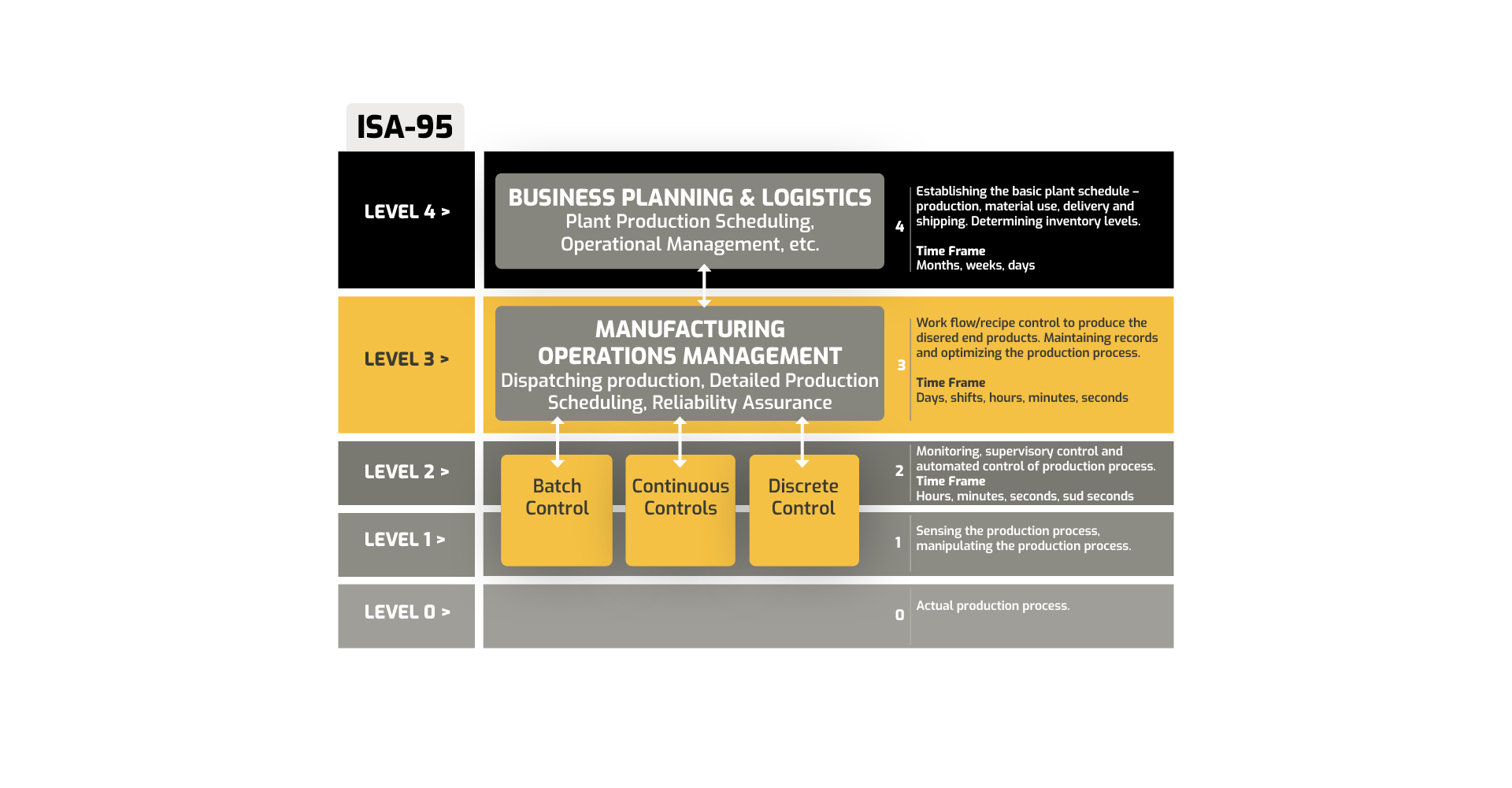

Leanware specializes in merging automation control into an efficient part of the production process. Automation is controlled with MES or WMS systems and there is no need for separate control systems or manual control. Automation is integrated as part of the system in accordance with the international standard ISA-95.

In the manufacturing industry we have merged automation to be a part of the total process in the material warehouse, in production part manufacture, assembly, intermediate storage and end product storage.

We always start with a Prestudy in which we review the automation choice and scaling needs. We find the challenges based on data and the most important development points that we can tackle together using control systems.