Well-functioning in-house logistics is the heart of an efficient factory. A digital factory requires an intelligent and guiding warehouse management system to ensure seamless and high-quality production, efficient logistics, complete transparency, and data-driven management.

“When seeking reform at this level, one cannot approach things by looking in the rearview mirror. Leanware challenged us to a very new way of thinking and contributed calculations to support decision-making. We noticed, among other things, that the number of material transactions in internal logistics seemed to indicate a need for simplifying material flows and seeking comprehensive solutions”

– Teija Pesonen, Development Engineer, Ponsse Oy

“In a rapidly growing company, the ability to increase capacity on short notice is crucial, and Leanware’s flexible team has helped us find the right solutions for this.”

– Daniel Asplund, Technology and Logistics Manager, Fresh Servant Oy

“In a setup like this, delays typically occur because the required part is not available. With LeanwareWMS, we can see in real-time the inventory status for each item, allowing us to anticipate production needs and necessary materials, thus mitigating potential delays.”

– Toni Teittinen, Assembly and Warehouse Production Manager, SEW Industrial Gears Oy

“We didn’t have internal logistics separated from production before. Now we do. It has brought a lot of new dynamics and clarity to our operations. With a smaller factory space and the same workforce, we can handle growing volumes, which is a very tangible benefit. We have managed to double production efficiency.”

– Mikko Heinilä, Production Manager, Isku

The LeanwareWMS (Warehouse Management System) is a more intelligent, guiding and efficient warehouse management system than ERP, and is managed by data – not by guesswork. WMS collects data on all operations, stores it in an easily analyzable format, and provides real-time situational information. This enables efficient daily management and continuous improvement of operations.

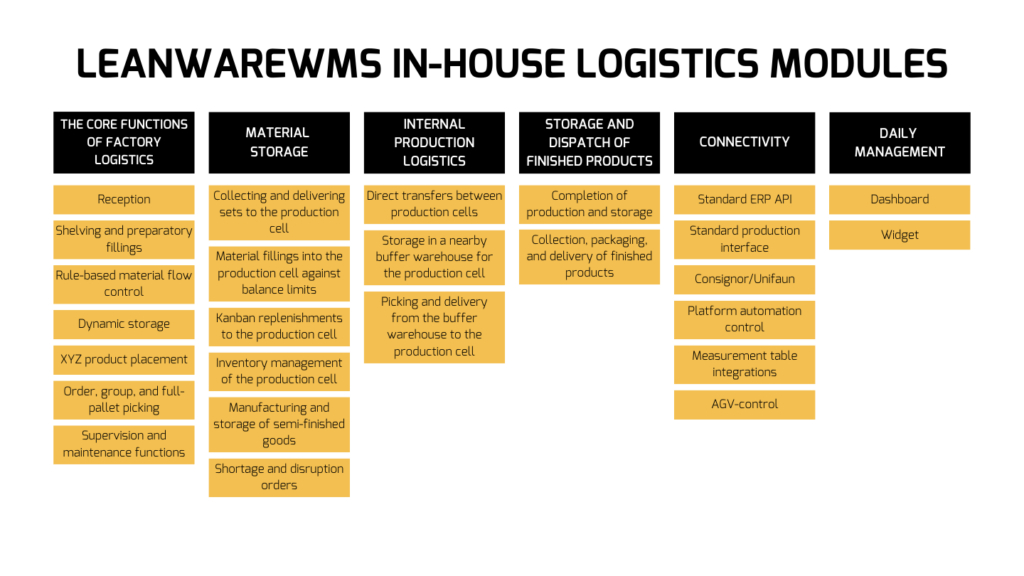

Factory environments bring their own unique requirements for internal logistics and warehouse management that WMS must address. LeanwareWMS is a comprehensive solution for the factory’s in-house logistics and improving production productivity, the total efficiency of logistics and quality. This translates to improved competitiveness for your business.

The software enables complete warehouse control through a single system, with ready-made integrations for common warehouse automation systems. Automation is an integral part of the entire process, and it yields maximum efficiency.

Well-functioning factory internal logistics has significant positive impact to production productivity. When logistics is able to faultlessly deliver the right materials at the right time to the right location, production personnel can fully concentrate on their tasks. LeanwareWMS’s intelligent control facilitates the transition to a more centralized and service-oriented logistics system that operates efficiently.

LeanwareWMS is suitable for comprehensive control of factory internal logistics, including material inventory, inter-stage production, and internal logistics for finished products. The software can be implemented incrementally and is easily connected with existing ERP and production systems. Furthermore, LeanwareWMS seamlessly integrates with automation, such as vertical lift systems and AGV (Automated Guided Vehicle) trucks.

To fully optimize factory operations, LeanwareWMS is tightly integrated with LeanwareMES, and LeanwareSCM procurement control complements the overall solution. Elisa IndustrIQ Finland’s Digital Factory concept provides solutions for digitalizing the entire manufacturing chain.

We are Microsoft’s ISV-partner (Independent Software Vendor).

Check out more