What could you find out about the cost efficiency of Amazon’s logistics? By the way, Amazon’s pricing is insanely transparent. It is a good resource for benchmarking. Amazon has two operating models, FBA and FBM. FBA = the product is delivered from Amazon’s warehouse and FBM = the product is delivered from the seller’s warehouse. In this article, I will focus on the costs of FBA.

Jonne Välilä from Amazon.fi notified me of the following page: //services.amazon.co.uk/services/fulfilment-by-amazon/pricing.html. Amazon’s pricing is incredibly simple: the use of storage space a month + processing fee. I made the toaster example on the web page the foundation for my calculations. So, the internal logistics of a toaster cost £4.09 + storage (1 month) £0.26 = £4.35 = €5.07.

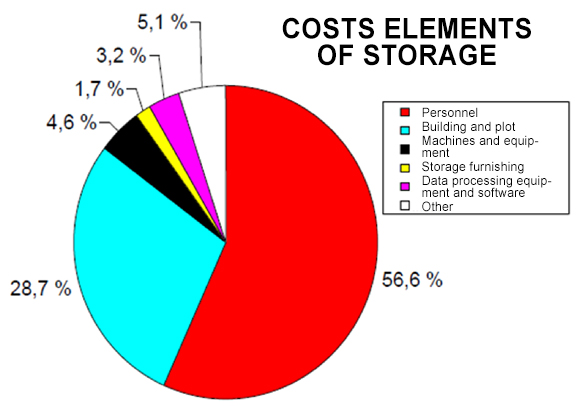

We can calculate the costs elements in accordance with the amazing (although old) Wadelma research (image below). According to rumours, a similar research has been repeated in England a few years ago and the percentages were close to those of Wadelma. (If someone could link the research, I would be very grateful.) So, from the €5.07, 56.6% is personnel costs, meaning €2.9 per row.

Here in Finland, our warehouse personnel costs are about €36,000 a year (meaning all costs, not just salaries), 200hrs on sick leave, 1,500hrs on row, which means that the work costs amount to €24 an hour.

This makes the overall efficiency: €24 per hour / €2.9 per row = 8.4 rows per hour. Does not sound too bad, right? Well, we can do better than eight rows in an hour! Here lies the most common pitfall: this is specifically about the overall efficiency per hour. Which refers to all departing rows’ relationship to all the work performed in the warehouse. Meaning that all supervisors, recipients, transporters, cleaners, inventors, collectors and packers have to be included in that. Unfortunately, we see a lot of warehouses where they try very hard, but the overall efficiency loses clearly to Amazon’s eight rows per hour.

I went over the last four initial warehouse reviews we here at Leanware have compiled. One warehouse came close, but the three others were clearly weaker. But our clients who implemented the LeanwareWMS system keep on telling us great success stories about how they have achieved a level of efficiency that clearly superior to Amazon’s.

It is our vision to make Finnish companies the most competitive in the world and we are making possible by continuously improving our client’s internal logistics. With the status Amazon has in the market, the demands for storage efficiency are emphasized more than ever before. An initial review is our service that helps you get started: you are given an analysis of the current situation of your warehouse and also a wide variety of measure recommendations to help and improve it. Contact us and get the benefits of our vision!