When you want to reach everyone at the same time – choose LeanwareMES as your manufacturing execution system. MES makes work easier as information flows easily from operative management to the production shop floor.

“LeanwareMES as a local tool helps both installers and management in daily tasks. The real-time entry of exceptions reduces the need to rely on memory. Up-to-date information also shortens the learning curve, allowing an installer to move from one work station to another quicker than before.”

– Toni Salovuori, Production Manager, Metso Outotec Finland Oy

“We achieved the set goals working with Leanware. We were able to simplify the manufacturing process and increase efficiency, in addition to ensuring manufacturing quality also to the benefit of our customers. We have stayed on schedule and within budget. Leanware is a capable, flexible and agile partner.”

– Riku Niemi, Purchasing Director, Neles Oyj

“The components move along the lines at the factory. In this way they will not be broken and will not be forgotten in the wrong place. The savings can be seen, for example, in the fact that we now have 100 forklift trucks moving goods from one place to another. At the end of the year, there will be only five. “

– Mika Tyrväinen, Production Director, Isku Teollisuus Oy

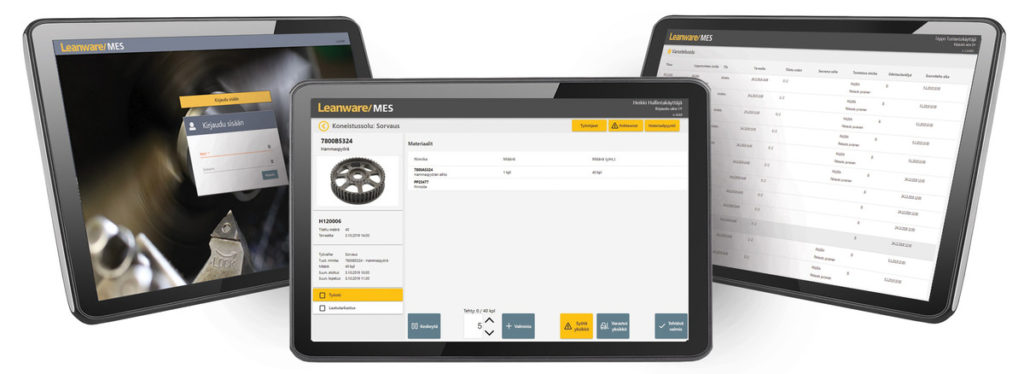

A manufacturing execution system or MES is intended for the management and tracing of the operations in production. MES transmits information between various systems and production automation. MES is the missing piece between ERP and production. The LeanwareMES system is available as both a SaaS and on-premises.

With the LeanwareMES system, production becomes more transparent. Information and instructions run digitally without rolling papers. Information travels from management to production workers, as well as to machines and equipment, and equally in both directions.

In addition to the employee, the LeanwareMES system controls automation and material flows, reducing unnecessary waste.

We are Microsoft’s ISV-partner (Independent Software Vendor).

Read more